The sand washer is a kind of highly-efficient sand washing equipment, combining the advanced techniques and the domestic physical conditions of sand industry.Sand washing machine is sand washing plant, mainly used for removing dust in the ore. Impurity and dust are removed in the artificial sand production process. According to its shape, sand washing machine can be divided into spiral sand washing machine and bucket sand washer. The sand washing machine has the advantages of high cleanliness, reasonable structure and high productivity. During the washing process, little sand runs off. The transmission part is separated from the water and the fault rate of the sand washing machine is further lower than the commonly used sand washing machine, making the best upgraded equipment in the sand washing machine.

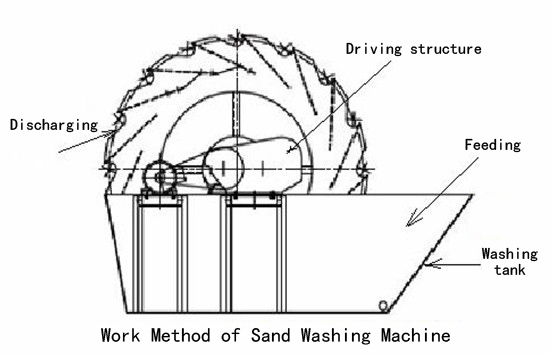

The bucket sand washer is basically made up of the lifting device, the rotors, the box and the dynamical part.

The motor, the speed reducer, the bevel gear, two pairs of coupling and the screws constitute the lifting device. The lifting device is connected by the lead screw. The lead screw and the screws are used for lifting the rotors. The back of the lead screw is connected to the lifting axis box, the abrasion-resistant rubber blankets of which are layered. One end of the center shaft is laid on the rubber.

The rotor part of mineral sand washer is composed of the center shaft, the swallow tailed iron and the screw vanes. The center shaft has the longer half and the shorter half at the ends. The longer half is tightly fixed in the bearing. Hoops, on which the angle steel is soldered, are welded on the center shaft. The swallow tailed iron, the big screw vanes and the abrasion-resistant impellers fixed by the screws should be installed based on the instructions in the pictures. On the rotors of small type classifier, the impellers are generally fixed directly on the swallow tailed iron. The impellers are double lined and rank in order according to the screw distance determined by the technology.

The box of mineral sand washer is made up of the portal frame which supports the lifting part, shell and plate welded by channel steel. There is guide rail soldered by steel plates near the inner side of the portal frame which prevents the lifting axis box from swinging when lifting materials. To contain more water for sand washing, the upper back of the box explodes open to both sides. There is an overflow tank on the upper side near the outside of the blind. The plate is determined by the length of the box and the installation of the dynamic part.

When the artificial sand washer works, the motor drives the impellers slowly after the v-belts, deceleration machine and gears slow down. The sandstone gets into the washing trough through the feeding trough and rotates and then will be ground driven by the impellers. The impurities on the surface and the water vapor coated layer enveloping the sandstone will be removed for dehydration; and when added water, it will form a strong water flow. The impurities and the foreign matters of small proportion overflow from the port, achieving cleaning effect. The clean sand will be taken away by the impellers and poured into the discharge chute.

Henan Hongxing provides a wide range of artificial sand washers with various specifications and models, such as the belt sand washer. The belt sand washer features in high efficiency and low energy consumption. The artificial sand washers produced by Henan Hongxing are warmly welcomed for reasonable price and sound services both at home and abroad.

| Specification | Processing Capacity (t/h) |

Motor Power (kw) |

| XS2308 | 15-40 | 4 |

| XS2711 | 20-65 | 5.5 |

| XS3014 | 50-100 | 7.5 |

| XS3220 | 80-200 | 11 |

| XS3227 | 100-260 | 15 |

| XS4215 | 200-300 | 15 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

You can also send a message to us by this email sales@hxjq.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

You can also send a message to us by this email sales@hxjq.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!